Breaking a perfectly good fuel pump

My Moto Guzzi has been running pretty rough lately. It wouldn’t start on my trip into San Francisco for a doctor’s appointment the day before Independence Day and I had to get it trailered back to Alameda. A couple of months ago I had a similar-seeming issue which was an electrical problem, but this did not seem electrical. The starter motor turned the engine over with vigor but the darn thing would not catch.

Next on my list of usual suspects is the fuel-air mix. The first thing I tried was cleaning the pod filters, which were filthy. The instructions in the K&N Recharger Kit say that the filters ought to be cleaned once every 50,000 miles. Clearly that is a suggestion for automobiles with K&N filters safely tucked under the hood in an engine compartment. For a motorcycle where the pods may as well be flapping in the breeze (and constant barrage of road grit) I’m guessing 10,000 miles might be a more reasonable interval.

After cleaning the pod filters the Nero Corsa started up again, but I began to have the same problems again within a couple days. When I rode to a motorcycle shop in Berkeley to buy brake pads, I ended up unable to start the bike while parked out front of a Yamaha dealer. The folks at the dealership were kind and helpful, but I couldn’t help thinking that having an Italian bike that won’t start out front is a pretty great advertisement for Japanese motorcycles.

Eventually I did manage to get back on the road, and made it back to Alameda. Troublingly, I nearly stalled out twice while on the freeway. I eventually pushed the fast-idle on to keep the revolutions from dropping too low. I was now absolutely determined to find the source of my fuel-air mix issue. Murphy’s law was in full effect and the bike was always starting with no trouble if I was close to home but dying and stranding me if I dared go farther than reasonable walking distance.

Thinking the fuel filter might be clogged or the fuel pump might not be doing its job properly, I decided to go after the issue by emptying the tank of its fuel and removing the fuel pump from inside the tank. The first part after siphoning out the gas is to disconnect the wires and hoses. The main intake and outflow hoses are connected by plastic nozzles with quick-release fittings that don’t actually quick-release. I managed to cut off one of the hose clamps1The hose clamps were not meant to come unclamped. Before I cut anything, I bought new hose clamps which tighten by screw. and remove the hose, but the second (on the intake nozzle) snapped off under minimal lateral pressure. I really do mean minimal; I was trying to remove the hose clamp.

That’s a problem. Getting Guzzi parts can take a while, which means that I would be without a fuel pump for who knows how long. Then when I started looking for the replacement nozzles, I found that they are not for sale. If one needs to replace one of those two fragile plastic nozzles, the Guzzi-sanctioned way to do it is to replace the entire fuel pump assembly. That includes both nozzles, the aluminum mounting bracket, the pump, filters, all the internal wiring and tubes — everything. That’s a $550 assembly.

Even if I had $550 lying around I wouldn’t pay that much, just on principle. Of course I tested the pump by placing it in a bowl of fuel and connecting it to power and found that the pump was working fine. There was not even any sort of clogging. If the pump was bad I might consider replacing the whole assembly, but I’d be grumbling about it. If the pump itself had gone bad, I wouldn’t have had to buy the whole assembly — the pump itself is sold separately for much less than $550 — but if I had to I would have found a way. I was not about to spend $550 on a 75¢ plastic nozzle.

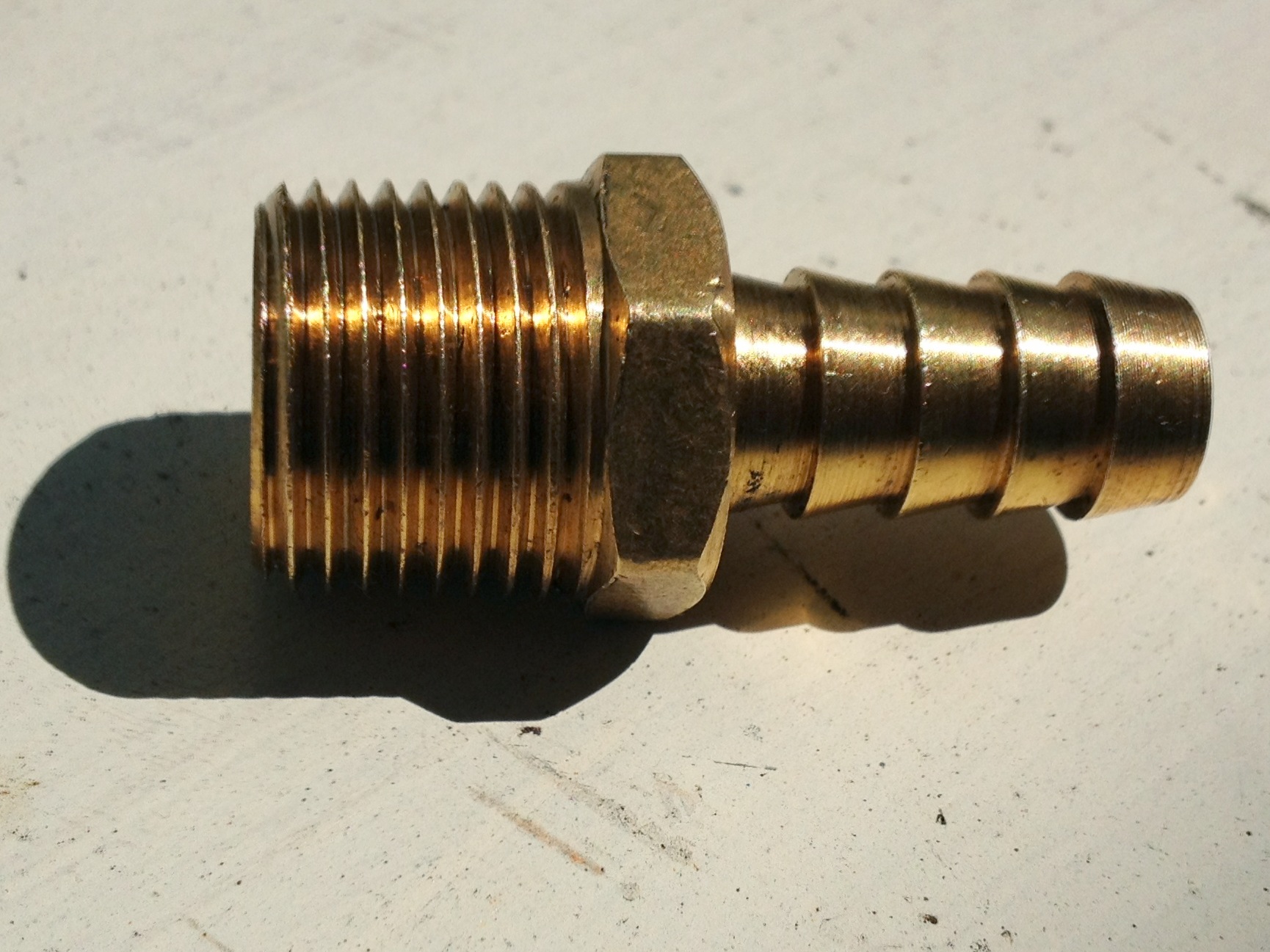

An Internet search found a number of people with a similar problem with various models of Guzzi. Some lucky person had another forum member mail a spare that had been sitting around, for free. There was some discussion about the possibility of getting the hole in the mounting plate cut with threads and fitting a brass replacement nozzle to it.

Emo’s Automotive Repair and Machine Shop here in Alameda agreed to give it a try for $55, despite the fact that Emo had his docket full and was getting ready to head out for vacation. He told me what I would need after spending a few minutes tossing around ideas and after one trip back to the driveway of Euthymia Labs (where the disassembled Guzzi was parked) to check the clearance below the fuel pump. Since a new nozzle would have to screw in to the threads that would be cut it would have to turn several rotations. A plain elbow fitting would not clear the output nozzle as it rotated. Either the replacement needed a riser of some sort or it needed to be a straight nozzle fitting. Either way would require more clearance than the old plastic nozzle.

$55 is a lot to spend on one nozzle, but of course I was not just buying a nozzle. Spending money on skilled labor is something I don’t mind at all. Furthermore, a brass fitting instead of a plastic nozzle will undoubtedly be more durable. Combine durability with simplicity and we have a winning solution. Add in supporting a local businessman who does good work and we have a home run.

I scrambled around town trying to get the right fitting before Emo closed up shop. After two auto supply stores, I went to Pagano’s Hardware and found a nozzle that met Emo’s specifications. I rushed back and found Emo’s door still open even though it was a few minutes after closing. That was Monday evening. He said he’d try to get to it before going away for vacation Thursday. First thing Wednesday morning, Emo called to tell me that it was ready.

Much relieved, I picked the pump up. The new nozzle was installed with a bit of Teflon tape and Erik Miller’s assistance (Erik said Teflon tape can be a little tricky.) The fuel pump went right back in, I reattached the hoses with the new hose clamps, plugged the electrics back in and the Guzzi started right up.

Once.

Actually, that’s not true. It started fine several times over the course of the next couple days. A couple times it didn’t start right up the first time but the second time I tried it it fired up. I figured that was something I ought to keep my eye on in case it got worse. I needn’t have bothered paying it any attention because Saturday evening when I went to pick up some prescriptions from the Costco pharmacy in San Leandro it started perfectly, got me as far as San Leandro, and then would not start once I finished with Costco.

I spent over two hours at Costco trying to bumpstart the Guzzi, trying to troubleshoot the fuel line, and looking for any electrical issues. I was getting nowhere both literally and figuratively until help (Matt Fe2O3 who answered my SOS on the Bay Area Riders Forum) was a few minutes away. A Costco employee who was leaving work offered to push the bike to help me bumpstart it, and this time it worked. I called back Matt and told him that he could go home but he suggested that he come along anyway to follow me and make sure I would make it home safely.

Good thing he offered because I got out onto Doolittle Drive and felt the bike hesitating. It was almost — but not quite — like running with only one cylinder firing. It felt as though it was failing to fire one time out of every three. Then almost within sight of the Bay Farm Island Bridge the Guzzi sputtered to a stop and would not start again.

Matt brought out a battery (even if there was no problem with the charge before I spent two hours turning the motor over without the engine catching, it was almost certainly low now) and we started troubleshooting and testing, this time quite literally at the side of the road with Matt’s SUV’s blinkers on.

More than an hour later (it was 9:30 and we were working by flashlight) the bike mysteriously started running. We began packing up the tools but just as the seat went back on the bike and we were getting ready to go the bike stalled out completely and again would not start.

We pushed the Guzzi to the Park ‘N’ Ride by the Chuck Corica Golf Course after I considered how fun pushing the bike two miles home would be. Once the Guzzi was locked down in the lot, Matt gave me a lift the rest of the way to Alameda.

I returned to the bike early on Sunday with Erik and a multimeter. After confirming that it seemed like a fuel starvation issue we got a bottle of injector cleaner and poured it in the tank, hoping that if the injectors were clogged that maybe we would luck out and get the bike to run for a minute or two again, long enough for some of the cleaner to make its way through the system.

After taking a break with a refreshing Arnold Palmer250/50 mix of iced tea and lemonade. The Arnold Palmer might be called the refreshingest beverage on Earth except that «refreshingest» isn’t a real word. we went looking at the electrics. Electrics had been high on the list of causes as the whine of the fuel pump cycling up could only sometimes be heard when the ignition key was turned. Erik read the electrical diagram from the shop manual while I turned the ignition key on and off until he followed the fuel pump circuit back to the relays.

We had swapped the fuel pump relay with relays from other positions three times before the testing with the multimeter began, and swapping the relay had not done any good. But there was still one relay that had not been swapped in to position to make it the fuel pump relay, so we gave it a go.

Bike started right up, no trouble. It kept running, no trouble, all the way back to Euthymia Labs. There it started again and ran fine all the way home. No stalling, no hesitations, no misfires. Today the bike has again been running well. It accelerates more smoothly than it has in months, suggesting that the relay had been slowly flaking for some time.

I ordered a bunch of relays from DesignTech Engineering that should keep me in spares for a while. Until then, I hope that whatever flaky relays I have plugged in are non-essential enough that I’ll get by until my relay shipment arrives.

For now I’m glad to know that I have at least one fuel nozzle that is unlikely to break if I look at it too hard. I’m a little mad at myself for breaking the nozzle in the first place. It’s a tad frustrating that I managed to break a part that wasn’t even malfunctioning. I had more to fix after I started repairs than I did when the bike simply wouldn’t run.

Then again, if fixing motorcycles was easy, everyone would be doing it.

- 1The hose clamps were not meant to come unclamped. Before I cut anything, I bought new hose clamps which tighten by screw.

- 250/50 mix of iced tea and lemonade. The Arnold Palmer might be called the refreshingest beverage on Earth except that «refreshingest» isn’t a real word.

Any Italian bike…

…is always a good advertisement for Japanese motorcycles. I can think of few good reasons to own anything other than a Japanese bike, except that some people think they are cool.

Dad

Cool non-Japanese bikes

Ouch. Dad, that hits a little too close to home.

Let’s just say that if I had a Japanese bike I wouldn’t be learning so much about fixing motorcycles and leave it at that.

Don’t take it personally!

All of my motorcycles with one possible exception have been non-Japanese. That one possible exception depends on whether or not you consider a Honda 90 to be a motorcycle. 🙂 I am pointing a lot more fingers at myself than at you!

Dad